SUSTAINABILITY

Responsibility and research, for an increasingly ethical and sustainable business.

Workers’ rights and environmental protection are two essential aspects of Elleti Group’s vision, making denim the manifesto of unique and one-of-a-kind identities, which are conveyed through the use of safe and low environmental impact treatments and processes. Aiming to the advancement of the aesthetic vocabulary of its clients, the results of this sustainable journey are shared by every center of excellence of the group, as part of a virtuous cycle of mutual improvement.

SUSTAINABILITY

Responsibility and research, for an increasingly ethical and sustainable business.

Workers’ rights and environmental protection are two essential aspects of Elleti Group’s vision, making denim the manifesto of unique and one-of-a-kind identities, which are conveyed through the use of safe and low environmental impact treatments and processes. Aiming to the advancement of the aesthetic vocabulary of its clients, the results of this sustainable journey are shared by every center of excellence of the group, as part of a virtuous cycle of mutual improvement.

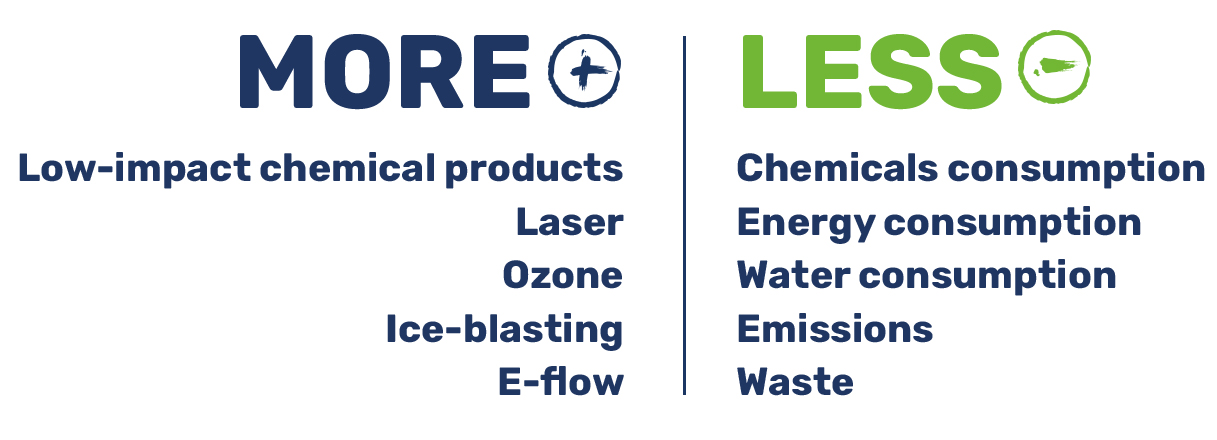

Earthkeepers

Sustainable and authentic, since 2011.

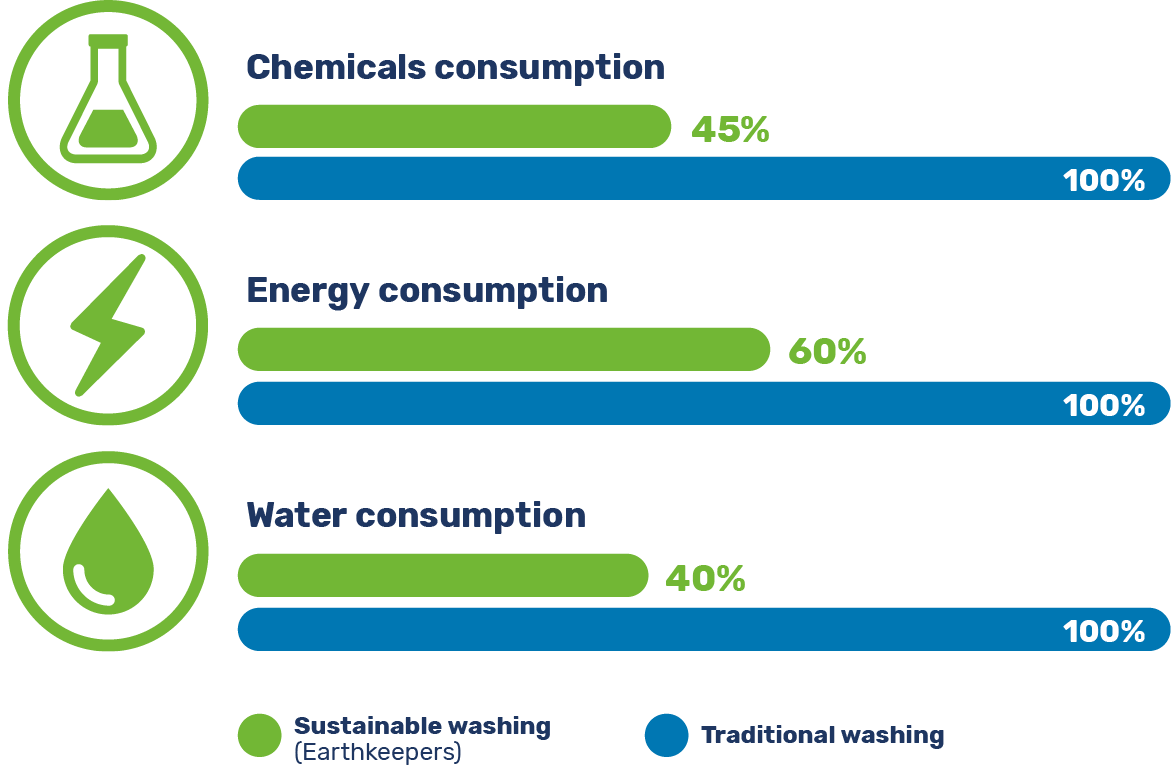

The effort and the commitment to the development of an increasingly sustainable collection finds its truest expression in Earthkeepers. This project, launched in 2011 and still ongoing, combines five technologies that couple the highest quality, featuring a genuine and authentic look, with a sustainable production, in full observance of resources, environment, and workers.

/ LASER

The alternative to traditional methods of bleaching, abrasion, decoration, marking, incision and cutting of the fabric. The precision of the machinery allows the processing of a great variety of patterns and effects in a timely and responsible manner.

/ OZONE

Ozone allows very fast and safe processing, thanks to its natural bleaching property that treats and intervenes on the fabric. This paves the way to multifarious possibilities of personalization in terms of water and chemicals consumption, pollution production and use of machinery.

/ ICE-BLASTING

Sand-blasting has evolved into ice-blasting, which is employed for localized abrasion on jeans. The treatment replaces sand with a high pressure ice jet, resulting in overall waste and chemical saving as well as providing a significant increase of the security level in the workplace.

/ NEW CHEMICAL PRODUCTS

The application of new chemicals, studied and developed to guarantee top quality and high safety standards, avoids the use of substances harmful to man and the environment – like clorine – during processing stages with a reduction in the use of water and energy during the process.

/ NANO BUBBLE TECHNOLOGY

By exploiting the creation of air nano bubbles to carry the chemical agents onto the garment, where they are evenly distributed guaranteeing the highest quality, this technology allows a 70-90% reduction in water consumption.

Partnerships and certifications, a real commitment

for a more sustainable production.

OEKO-TEX®

A worldwide consistent, independent testing and certification system for raw, semi-finished, and finished textile products at all processing levels. Renowned on a global level, it guarantees that the products tested do not contain harmful substances.

OHSAS 18001:2007

Conceived in relation to occupational health and safety management, this international standard provides a framework to identify, control and decrease the risks associated with these two specific topics within the workplace.

ISO 14001:2015

This certification specifies the requirements for an environmental management system that an organization can use to enhance its environmental performance.

ISO 9001:2015

It evaluates the appropriateness and effectiveness of Quality Management Systems helping to identify and implement improvements.

ZDHC – Zero Discharge Hazardous Chemicals

The commitment to the ZDHC Foundation’s Roadmap to Zero programme embodies Elleti Group’s effort toward zero discharge of hazardous chemicals in its supply chain.

Fair Wear Foundation

In collaboration with brands, key players, and influencers, the organization acts and operates to improve the working conditions in the facilities of the manufacturing industry.

SMETA

Developed by Sedex, it is a non-profit organization committed to the promoting of ethical principles in the supply chains across the world. This audit methodology provides a compilation of best practice ethical audit techniques in respect to working conditions, health and safety, work environment and business practices.